Eye care professionals rely on precise measurements to diagnose and monitor glaucoma, among other eye health issues. Tonometers measure intraocular pressure, but their accuracy and safety depend heavily on proper maintenance and hygiene protocols. Tonometer tip covers serve as an important protective barrier, keeping measurement precision while preventing cross-contamination between patients.

This ultimate guide to tonometer tip covers examines the key things to know about these products, including safety benefits, proper selection, and usage protocols.

Understanding Tonometer Tip Covers

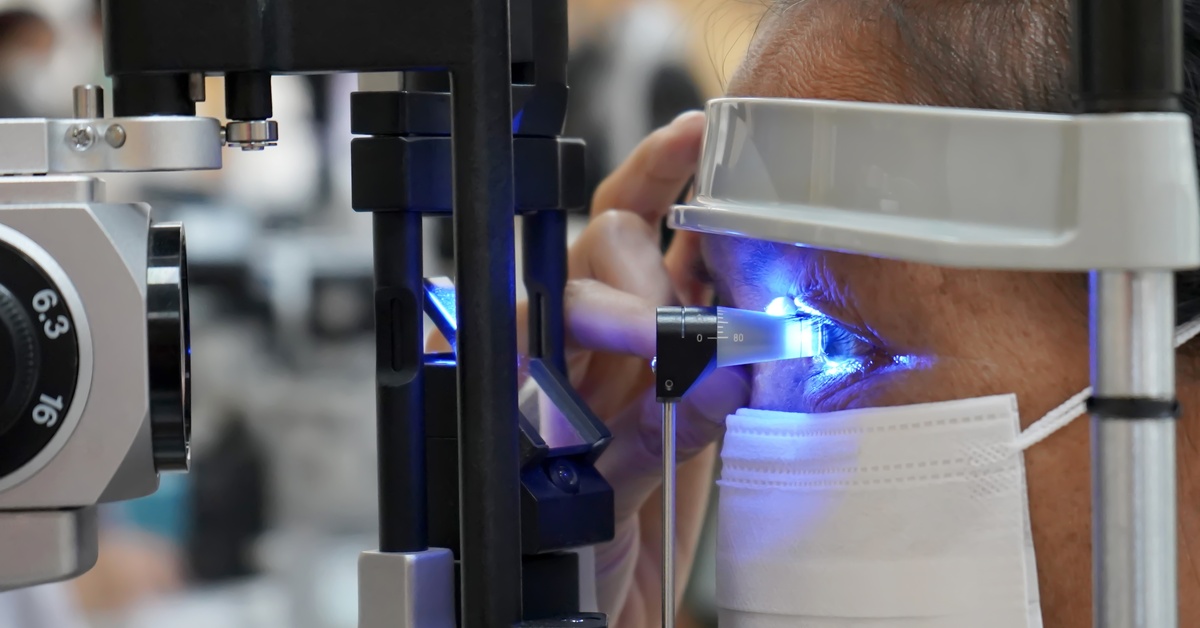

Tonometer tip covers represent specialized protective barriers made specifically for applanation tonometry procedures. These thin, transparent covers fit securely over the tonometer tip, creating a sterile barrier between the instrument and the patient’s eye. Healthcare providers use these covers to uphold hygiene standards while preserving the accuracy of intraocular pressure measurements.

Medical-Grade Materials

The latex used in tonometer covers is a biocompatible, medical-grade material, preferred for its exceptional elasticity, thinness, and durability. These properties allow for a snug fit, facilitating accurate intraocular pressure readings and effective contamination prevention. Latex’s combination of strength, sensitivity, and affordability makes it superior for safe, accurate ophthalmic applications.

Infection Control Benefits

Cross-contamination prevention stands as the primary advantage of using tonometer tip covers. Direct contact between the tonometer and the patient’s eye creates potential pathways for transmitting infectious agents, including bacteria, viruses, and other pathogens. Covers eliminate this direct contact, significantly reducing the risk of infection transmission.

Measurement Accuracy Considerations

High-quality tonometer tip covers add minimal thickness to the instrument’s tip, resulting in a negligible impact on pressure readings. Healthcare providers can trust that cover usage won’t compromise diagnostic accuracy when they select appropriate products.

Inferior covers may introduce measurement errors through uneven thickness, optical distortion, or poor fit. Automated Ophthalmics has conducted extensive research on cover performance characteristics to help clinicians understand these critical factors.

Proper Application Techniques

Correct cover application guarantees the best performance and patient safety. Healthcare providers should inspect each cover before use, checking for tears, holes, or manufacturing defects that could compromise barrier protection. The cover should fit snugly over the tonometer tip without wrinkles or air bubbles that might affect measurements.

Storage and Handling Requirements

Proper storage protects the integrity and sterility of the cover. Most manufacturers package covers in sterile containers or individual pouches that protect against contamination until they are used. Healthcare facilities should store covers in clean, dry environments away from direct sunlight and extreme temperatures. Tip covers should be stored between 36 and 80° Fahrenheit.

Making Informed Decisions

High-quality tonometer tip covers offer reliable protection and measurement precision. Investment in top-of-the-line products like Tono-Pen covers demonstrates a commitment to safety and diagnostic accuracy that your patients’ eye health requires.

Now that you have reviewed this ultimate guide to tonometer tip covers, the next step is to select the appropriate tonometer tip cover. After establishing instrument compatibility, measurement accuracy requirements, and budget constraints, you’ll want to find a dependable supplier.

Automated Ophthalmics does everything in-house—including manufacturing and supplying—guaranteeing consistent and convenient access to the bulk orders you need. Reach out to us to learn more about high-quality tonometer tips today!